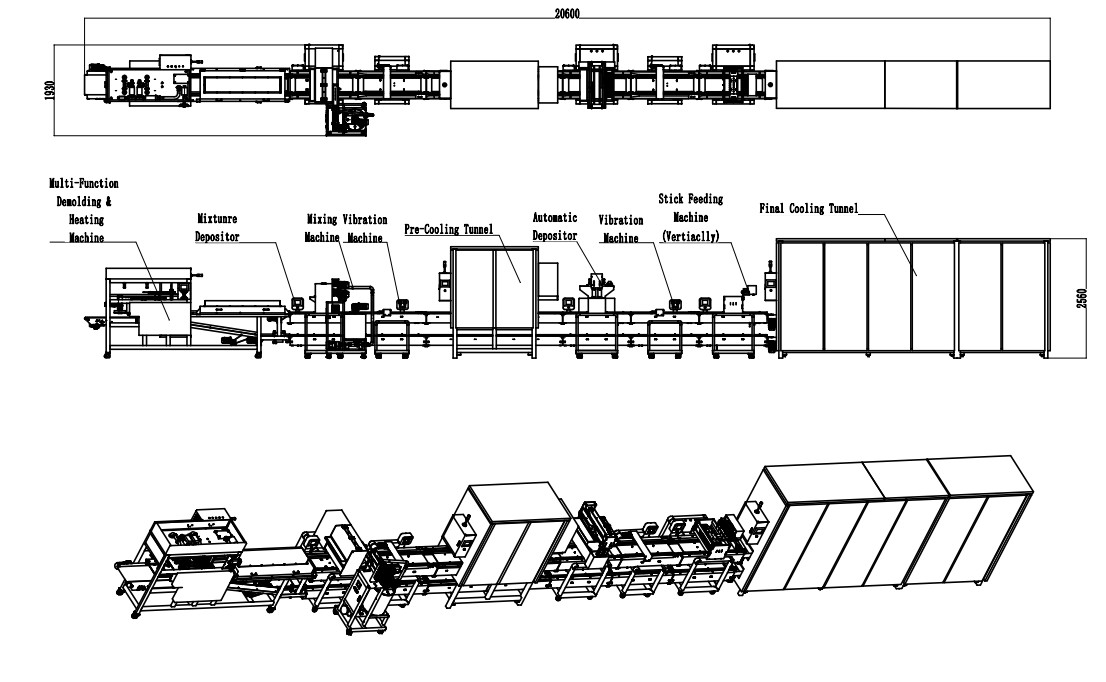

Chocolate Mixture & 2-color Ice cream Stick production line(MF-ML)

Description

Reviews

Mixture Chocolate Ice-Cream/Lollipop

Let’s upgrade it with your imagination!

■ Double colors let the product more beautiful.

■ Dry Fruit has excellent taste and strong chewiness.

■ Higher nuts inclusion percentage makes the chocolate more crunchy.

■ Different shape of sticks looks more interesting.

There is no electrical and air connection on the top of the Depositor. Although each machine is stand-alone unit, but the electricity and air of each machine can be connected to the adjacent machine. So it can be combined flexibly as per your requirements to bigger capacity or more functions.

Our technical team is the originator and developer of this technology

Some products with different inclusions from Hershey’s, Mars, Godvia also produced by this line.

■ “Fast - Linear Modular” design, the amazing part of this design is that it can adapt almost all different user’s requirements;

■ “Space-Saving” Only need 50% workshop space of “Ring-like Modular” line. Bigger capacity in same workshop.

■ “Upgradability” More modules developed every year. All the line can be upgraded to more functions and higher capacity.

■ “High efficient”Advanced design, mature technology make the installation and commissioning very easy. User can easily handle it and quickly run the production.

Let's take a look at the specific modules of this chocolate lollipop production line

Multi-function pre-heating and demolding machine

■ Multi-function. Including Vacuum Demolding, Knock Demolding and Automatic Boxing to meet users’ different requirements.

■ Fast Speed. Maximum 14 mold/min. If the speed still not enough, there are bigger capacity demolding solutions.

■ Including heating function. Precise temperature control, sufficient hot air circulation, flexible parameter setting.

Mixture Depositor & Mixing Machine

■ Suitable for mixing various inclusions, crisp and hard granules, e.g. nut granules, crispy rice etc.

■ The mixture volume ratio up to 50%;

■ Max. diameter of the mixing granule up to 12mm;

■ Liquid level control: Automatically control material delivery according to the liquid level limit;

Vibration Machine

■ Vibration & Swing mode balancing as per material status;

■ Vibration and swing frequency is adjustable and controlled by converter

Pre-cooling Tunnel

■ Cooling system is air-cooled, no need to connect pipeling, free movement and combination;

■ Two operation modes, if the product no need precooling in the future, molds can go through directly from the bottom of pre-cooler, improve production efficiency;

■ The cooler adopts integrated design, saving energy and reducing consumption;

Stick-feeding Machine

■ Suitable for plastic round stick, paper round stick horizontal placing, 6-8 molds per minute;

■ The upper conveyor is designed for synchronous belt without running deviation;

■ The lower conveying is chain plate design, easy to change with a low cost;

■ The machine is on wheels,can be change place quickly.

Automatic Depositor

● Food grade hose connected to the depositing plate;

● The upper conveyor is designed for synchronous belt without running deviation;

● The lower conveying is chain plate design, easy to change with a low cost;

Final Cooling Tunnel

■ Adopt lifting technology, advanced design allows the equipment to adapt to various products heights

■ Good humidity control system, which is suitable for biscuit products production,

■ High efficient, up to 14 molds/min. Excellent cooling system and energy saving.

Do you want to know what else products can be made on this line?

One shot, 2 colors, bar chocolate can be made by this line only need to change the depositing plate and demolding plate.

With center filling

With decoration

With lollipop

Even change product type by adding different functional machine

Our modular technology and innovation ability will keep chocolate line advanced for many years.

For more information about the production line, or you want to visit the production process on line. Please contact our export manager.