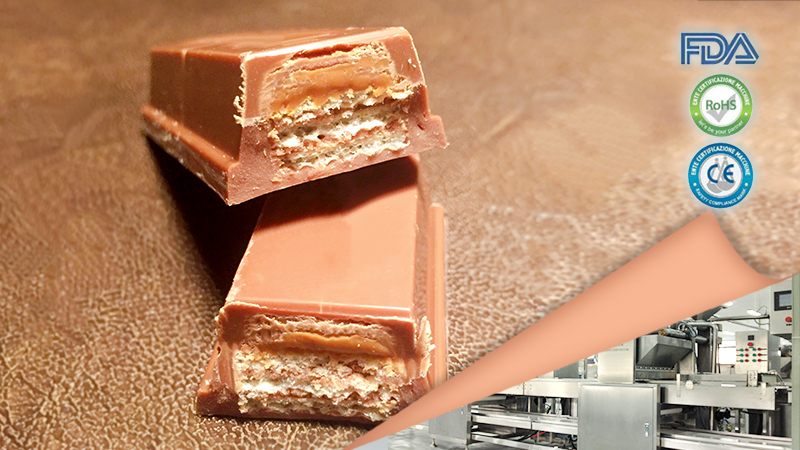

WAFER & other fillings chocolate shell molding line(MF-WF)

Description

Reviews(1)

UPGRADING is one of the easiest ways to innovate successfully.

If inside kitkat not only wafer, but also soft filling or mixture, will the taste be great? Let's take a look!

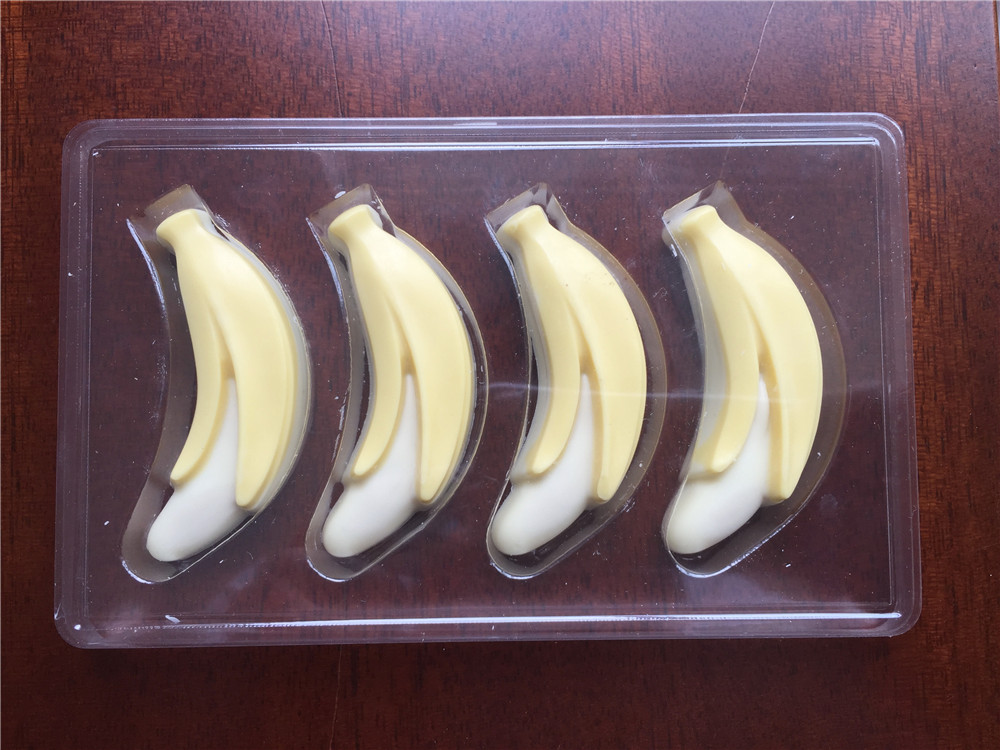

It is Wafer & other SOFT FILLING chocolate.

Our technology and creativity can upgrade MIXTURE FILLING chocolate as below.

BISCUIT FILLING & Butter FILLING

WAFER FILLING & Caramel FILLING

■ Chocolate has both soft filling and wafer or biscuit taste.

■ Adoption of shell molding technologies is suitable for much more kinds of materials.

■ Combination with decoration technology makes the product better.

Do you want to know how to make Wafer & other fillings chocolate?

Many MIXTURE FILLLING chocolate is made on this line.

Shell molding Technology

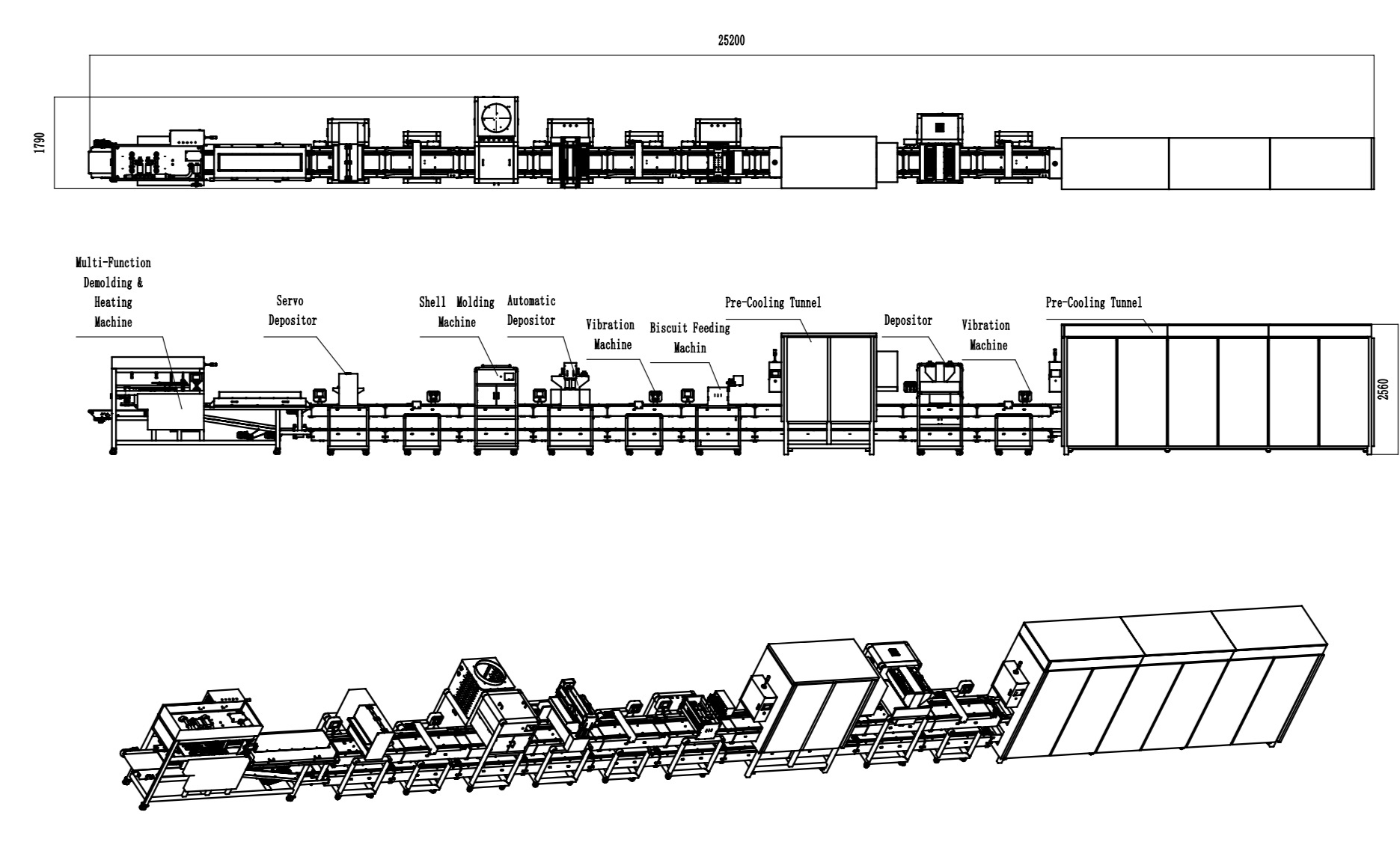

This Wafer & other fillings chocolate production line looks some different, right?

It can be flexibly combined according to the needs of the production process

Our technical team is the originator and developer of this technology.

Similar products of Mars, Hershey and Godiva have been produced by this series lines.

Let's take a look at the special features of this production line

■ It is “Linear Modular Design’’. The magic of this design is that it enables this molding line very flexible and can almost make all the chocolate available today and in future.

■ The space occupied of production line is only 50% of the ring modular equipment, the same workshop will create more capacity for users.

■ The production line adopts CNC depositing technology, and the energy consumption is only about 65% of the heavy CNC production line, which saves considerable using cost for users.

■ Reliable and uniform cold air transferring makes shell molding work more efficiently,the specially cold structure design reduces requirements of cold press for environmental humidity.

■ The biscuit feeding equipment which is customized according to the characteristics of customers and biscuits improve production efficiency.

■ The rich functional modules support the future development of users and enables them expand the required functions and capacity flexibly.

■ Advanced design and mature technology makes installation and debugging very easy, users can easily handle equipment installation and production.

■ There are 2 types production line: 5-6 molds/min and 10-12 molds/min (according different colors and shapes)

Let's take a look at machines included of the production line and what are the characteristics of these equipment?

Multi-function demolding machine

■ Multi-function: vacuum demolding, mold tapping and automatic packing to meet the demolding needs of different products of users.

■ Fast demolding speed: max 14mold/m, bigger capacity is also available.

■ Heating machine: mold heating, accurate temperature controlling, sufficient hot air circulation, the parameter setting is flexible and convenient.

Multi-function CNC depositor

■ Compared with 200kg heavy depositor moving parts, the weight of the light CNC depositor moving parts is less than 10 Kg, and the running is light and fast, the energy consumption and use cost are greatly reduced, and the reliability is greatly improved.

■ The standard depositor is equipped with 48 sets pistons, depositing accuracy can be up to ±0.1g. Bigger capacity is also available.

■ Depositing speed is normally 6-12 mold/min, it varies according to the mold layout and difficulty of product shape.

Vibration machine

■ Vibration and swing, two ways for choice to balance material according to different material.

Pre cooling tunnel

■ Using lifting technology, customer can choose pre-cooling or pass it directly if the product do not need pre-cooling.

■ All stainless steel material, 48 molds can be accommodated, precooling temperature, operating speed and other parameters can be set ;as request.

■ Refrigeration integrated machine, when recombining the production line, no need to connect another pipeline, the machine can be re-positioned flexibly.

Cold press machine

■ Reliable and uniform cold air transferring makes shell molding work more efficiently.

■ The specially cold structure design reduces requirements of cold press for environmental humidity.

Wafer Feeding System

■ Cutting, Aline, Feeding Wafer System.

■ Flexible design, the machine can be adapted to different biscuit feeding.

Energy saving final cooling tunnel

■ Lifting structure and advance design concept, this machine is suitable for different height product.

■ Good humidity controlling enable it is good for biscuit chocolate making.

■ High efficiency, max 14 mold/min, excellent refrigeration and energy saving.

You must want to know what else products can be made on this line?

Shell molding, One shot, decoration chocolate can be made by this line only need change another depositing plate and demolding plate.

Our modular technology and innovation ability will keep chocolate line advanced for many years.

For more information about the production line, or you want to visit the production process on line,please contact our export manager.